OUR SERVICES

Energy Efficiency Programs

The Renovale's energy efficiency programs aims to reduce energy consumption. Many companies can halve their energy costs only with a better energy management. It is estimated that up to 20% of energy savings can be achieved through addressing measures that do not entail additional capital expenditures.

Program Measures:

- Adoption of intelligent and most efficient lighting systems;

- Improvement of building fabric and thermic isolation;

- Enhancement of heating and hot water systems;

- Energy analysis of boilers and steam distribution systems;

- Evaluation of ventilation and air conditioning systems;

- Company layout optimization;

- Adoption of more efficient equipment;

- Energy diagnostics of the utilities sector, including compressed air and refrigeration systems.

Program Steps:

- 1. Data collection: our technical team will make a visit to your company to collect data regarding your energy consumption.

- 2. Energy analysis: identification of the opportunities for energy savings.

- 3. Brainstorming: proposition of measures to achieve these opportunities and estimation of how much energy can be saved.

- 4. Measures implementation: will have priority those measures which have the greater energy reduction potential and lower execution costs.

- 5. Energy audit: the effectiveness of the measures will be monitored through new data collection.

Waste Management

Our waste management plans are based on the concept of waste hierarchy, such as the application of the 3 R’s (reduce, reuse and recycle) and thereafter, the appropriate waste treatment and disposal. The plans also include elements of selective waste sorting, reverse logistics and product lifecycle management.

Renovale prepares and executes the Waste Management plans, providing the necessary training for the effective application of these plans in your company. Learn about the main waste management plans:

Industrial and Hazardous Waste

The management plan contains information about all residues originated in the company's production process, in terms of their generation (characterization and quantification), flow (how they are collected and stored until collection) and final disposal (treatment and recycling).

Medical and Biomedical Waste

The waste generated by health care activities, such as pharmacies, hospitals, medical clinics, dental practices, universities, research institutions, laboratories and veterinary clinics is of a biohazardous nature and follows specific legislation. Materials such as blood, body parts, dead animals, used gloves, chemicals, drugs, razor blades, broken tubes, needles, syringes, used medical equipment and devices are considered as medical or biomedical wastes.

Construction and Demolition Waste

Construction and demolition wastes consist of unwanted material produced by the construction industry. The wastes produced in these sites include asbestos, soil, rubble, concrete, steel, metal, bricks, ceramic materials, wood, glass, plaster, plastics, rubber, papers, paints, solvents, lighting, electric and plumbing fixtures.

Chemical Safety

Renovale prepares, evaluates, reviews and adapts the main chemical safety documents required by the legislation:

SDS - Material Safety Data Sheet

All manufacturers and suppliers of chemicals should have indicative sheets for each of their products, elaborated according to the GHS. The SDS, also known as MSDS, contains detailed and essential information about the physical and chemical properties of a given chemical and its inherent hazards regarding health, safety and the environment.

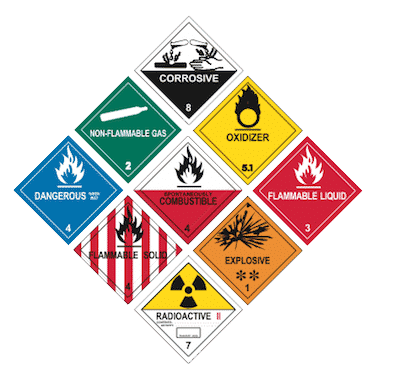

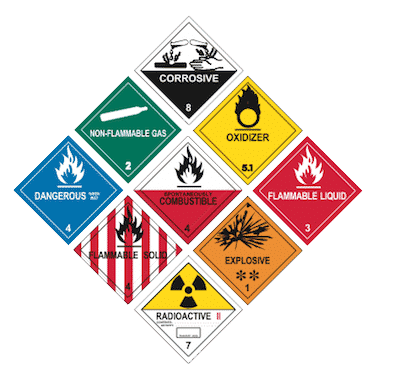

Hazchem and ADR

Required documents for the transport and storage of dangerous goods in the Commonwealth countries and the EU, respectively. These documents consist of a warning plate system stating the main risks of the product during its transport and storage and the measures to be taken in case of accidents.

NFPA 704

The “Fire Diamond” is a system used by emergency personnel for immediate assessment of the risks posed by dangerous materials. It indicates the severity of a potential hazard regarding to its flammability, reactivity, toxicity and specific hazards.

Cleaner Production

Cleaner Production is the continuous application of an economic, environmental and technological strategy integrated with the processes and products, in order to increase the efficiency in the use of materials, water and energy, with environmental and economic benefits for the company.

The actions typically adopted in a Cleaner Production program includes replacement of materials, energy conservation programs, layout optimization, inventory control, water reuse and integrated waste management.

The main results of a Cleaner Production program:

- Savings in materials, water and energy;

- Reduction of waste (through 3R's - reduce, reuse and recycle);

- Improvement of worker's health and safety conditions;

- Reduction of environmental accidents;

Energy Efficiency

The Renovale's energy efficiency programs aims to reduce energy consumption. Many companies can halve their energy costs only with a better energy management.

It is estimated that up to 20% of energy savings can be achieved through addressing measures that do not entail additional capital expenditures.

Program Measures:

- Adoption of intelligent and most efficient lighting systems;

- Improvement of building fabric and thermic isolation;

- Enhancement of heating and hot water systems;

- Energy analysis of boilers and steam distribution systems;

- Evaluation of ventilation and air conditioning systems;

- Company layout optimization;

- Adoption of more efficient equipment;

- Energy diagnostics of the utilities sector, including compressed air and refrigeration systems.

Program Steps:

- 1. Data collection: our technical team will make a visit to your company to collect data regarding your energy consumption.

- 2. Energy analysis: identification of the opportunities for energy savings.

- 3. Brainstorming: proposition of measures to achieve these opportunities and estimation of how much energy can be saved.

- 4. Measures implementation: will have priority those measures which have the greater energy reduction potential and lower execution costs.

- 5. Energy audit: the effectiveness of the measures will be monitored through new data collection.

Waste Management

Our waste management plans are based on the concept of waste hierarchy, such as the application of the 3 R’s (reduce, reuse and recycle) and thereafter, the appropriate waste treatment and disposal. The plans also include elements of selective waste sorting, reverse logistics and product lifecycle management.

The plans also include elements of selective waste sorting, reverse logistics and product lifecycle management.

Renovale prepares and executes the Waste Management plans, providing the necessary training for the effective application of these plans in your company. Learn about the main waste management plans:

Industrial and Hazardous Waste

The management plan contains information about all residues originated in the company's production process, in terms of their generation (characterization and quantification), flow (how they are collected and stored until collection) and final disposal (treatment and recycling).

Medical and Biomedical Waste

The waste generated by health care activities, such as pharmacies, hospitals, medical clinics, dental practices, universities, research institutions, laboratories and veterinary clinics is of a biohazardous nature and follows specific legislation.

Materials such as blood, body parts, dead animals, used gloves, chemicals, drugs, razor blades, broken tubes, needles, syringes, used medical equipment and devices are considered as medical or biomedical wastes.

Construction and Demolition Waste

Construction and demolition wastes consist of unwanted material produced by the construction industry. The wastes produced in these sites include asbestos, soil, rubble, concrete, steel, metal, bricks, ceramic materials, wood, glass, plaster, plastics, rubber, papers, paints, solvents, lighting, electric and plumbing fixtures.

Chemical Safety

Renovale prepares, evaluates, reviews and adapts the main chemical safety documents required by the legislation:

SDS - Material Safety Data Sheet

All manufacturers and suppliers of chemicals should have indicative sheets for each of their products, elaborated according to the GHS.

The SDS, also known as MSDS, contains detailed and essential information about the physical and chemical properties of a given chemical and its inherent hazards regarding health, safety and the environment.

Hazchem and ADR

Required documents for the transport and storage of dangerous goods in the Commonwealth countries and the EU, respectively. These documents consist of a warning plate system stating the main risks of the product during its transport and storage and the measures to be taken in case of accidents.

NFPA 704

The “Fire Diamond” is a system used by emergency personnel for immediate assessment of the risks posed by dangerous materials. It indicates the severity of a potential hazard regarding to its flammability, reactivity, toxicity and specific hazards.

Cleaner Production

Cleaner Production is the continuous application of an economic, environmental and technological strategy integrated with the processes and products, in order to increase the efficiency in the use of materials, water and energy, with environmental and economic benefits for the company.

The actions typically adopted in a Cleaner Production program includes replacement of materials, energy conservation programs, layout optimization, inventory control, water reuse and integrated waste management.